:2021-11-17 Source:ANDRITZ Category: Enterprise

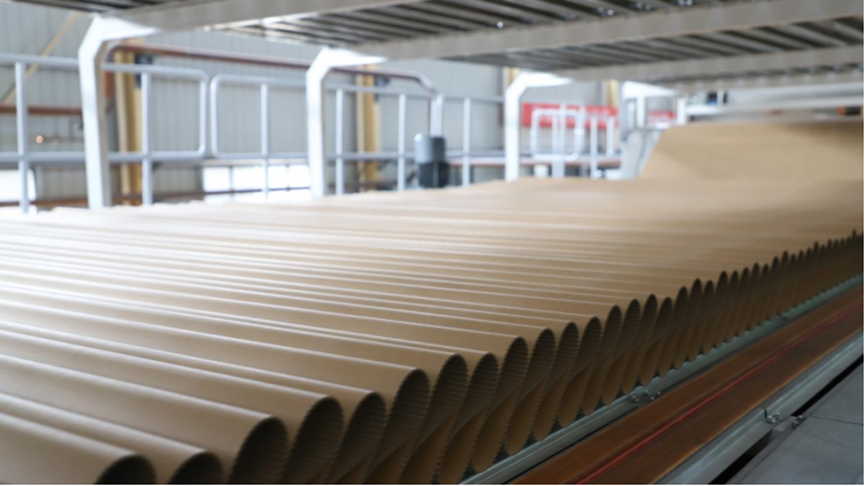

The proven ANDRITZ P-RC APMP (Pre-Conditioning Refiner Chemical Alkaline Peroxide Mechanical Pulp) line features a capacity of 600 admt/d and processes eucalyptus wood chips as raw material to produce high-quality pulp for the production of printing and writing paper. It is now the sixth

P-RC APMP line to be delivered to the Sun Paper Group by ANDRITZ.

The scope of supply comprises all key equipment for the fiberline, including the following technological highlights:

Two-stage impregnation system with outstanding MSD Impressafiners for efficient pre-treatment and optimum chemical impregnation of wood chips prior to refining

High-consistency (HC) refining stage with two parallel ANDRITZ S2070 single-disc refiners for superior fiber properties and highest production flexibility

Low-consistency (LC) refining stage with ANDRITZ TwinFlo refiners to develop optimal pulp strength at lowest shive content

Cao Yanjun, Vice General Manager at Sun Paper, comments: “In close cooperation with the highly dedicated team from ANDRITZ China, we were able to start up the new P-RC APMP line at our Beihai mill in only 24 days. That’s an impressive start-up curve! The new line is already delivering excellent mechanical pulp within such a short time for our top-quality paper production.”

Li Ke, Project Director, Paper, Fiber and Recycling Division at ANDRITZ China, adds: “It’s an honor to have Sun Paper among our key customers and support them in achieving their goals. Our mission is to focus on all aspects of the project – future-oriented line set-up, superior technology, and all-in service.”

Guangxi Sun Paper was established in 2019 to build an integrated pulp and paper mill in Beihai. The mill will be constructed in two phases over approximately five years. When completed, it will have a total annual pulp and paper capacity of 3.5 million tons.